Case Studies

Customer case studies are collected to showcase real-world examples of how our service delivers value to our partners.

FERNITE ENGINEERING - CUSTOMER CASE STUDIES

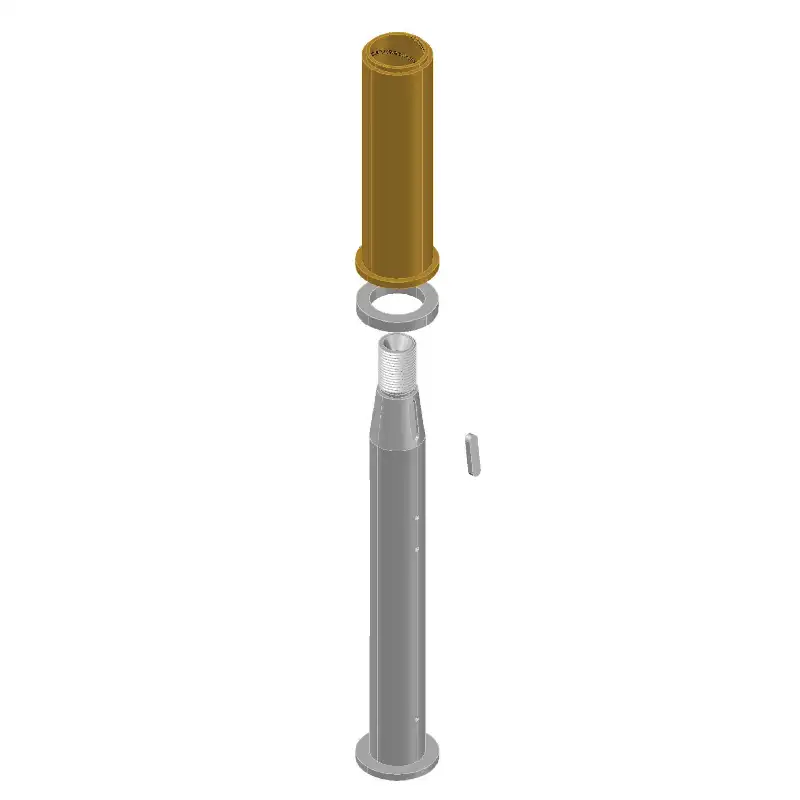

At Fernite Engineering, we’ve been supporting customers with Pendulum Mill refurbishments and upgrades for over 20 years.

Customer: UK Minerals Processor

Sector: Industrial Minerals

Service: Ongoing Pendulum Mill Maintenance and Refurbishment

Challenge

The customer was juggling multiple suppliers for different components and services related to their Pendulum Mill, leading to inconsistent quality, longer lead times, and increased administrative overhead.

Solution

Fernite Engineering offered a full-service maintenance solution, acting as the single point of contact for all mill-related needs. From routine wear part replacements to major refurbishment work, all services were carried out in-house to the highest standards.

Result

Fernite’s unified approach removed complexity, improved mill uptime, and delivered fast, reliable turnaround with guaranteed quality.

Fast turnaround and reliable

Fernite Engineering have removed all the hassle out of managing our mill maintenance. Their full-service approach means we only need one point of contact, and we always get fast turnaround and reliable quality

Customer: International Raw Materials Group

Sector: Global Industrial Processing

Service: Full Pendulum Mill Refurbishment

Challenge

The customer’s existing Pendulum Mill had seen years of hard operation and was no longer performing efficiently. Downtime was increasing and replacement parts were difficult to source consistently.

Solution

Fernite carried out a complete mill inspection, followed by a full refurbishment using precision-engineered replacement parts. Throughout the process, the customer received clear communication and expert technical support.

Result

The mill was returned in better-than-new condition, improving reliability and extending equipment life, saving the business significant replacement costs.

Honest advice

The team at Fernite Engineering refurbished our Pendulum Mill to better-than-new condition. Clear communication, honest advice, and top-quality engineering, we couldn’t ask for more.

Customer: Mineral Production Facility

Sector: Mining

Service: Design and Manufacture of a New Pendulum Mill

Challenge

The customer needed a brand-new Pendulum Mill, tailored to their unique processing setup. Performance, reliability, and delivery time were all critical requirements for their fast-moving operation.

Solution

Fernite Engineering designed and manufactured a complete new Pendulum Mill to the customer’s exact specification, using in-house fabrication, machining, and quality control processes to ensure high standards and delivery efficiency.

Result

The project was completed on time and on budget, with the new mill exceeding the customer’s expectations for performance and durability.

Exceeded expectations

We needed a full new Pendulum Mill built to spec. Fernite Engineering delivered on time, on budget, and exceeded expectations on performance.

-

- Quality

- Reliability

- Short Lead-Time

- Cost effective

- Fixed Pricing Structure