Pendulum roller mill manufacture

and refurbishment

We repair, refurbish and manufacture Raymond Roller Mill and Lopulco Mills for mining, mineral processing, cement manufacturing, chemical production, and other heavy industries.

What we do

Repair, Refurbish, Manufacture New

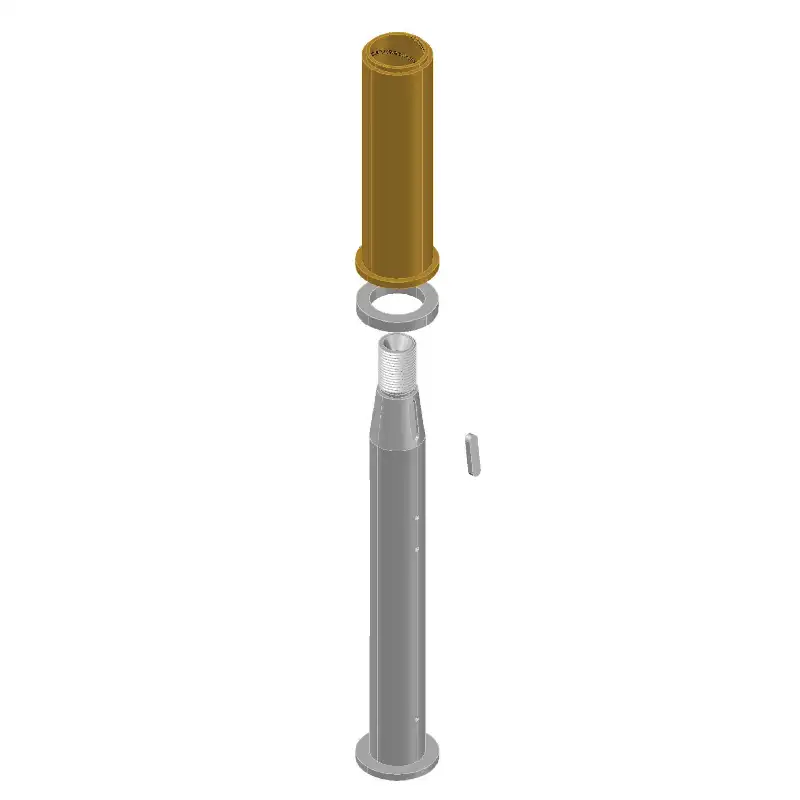

Pendulums

All wear-critical components can be engineered and manufactured to precise tolerances in accordance with application requirements.

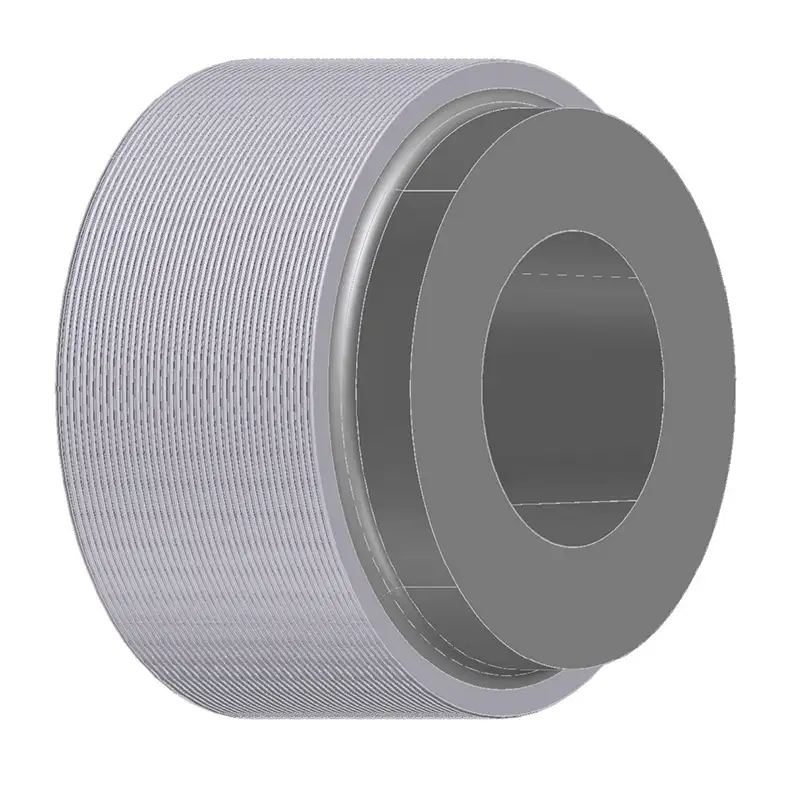

Bull Rings

Replacement rings are manufactured in-house to meet or exceed original equipment specifications.

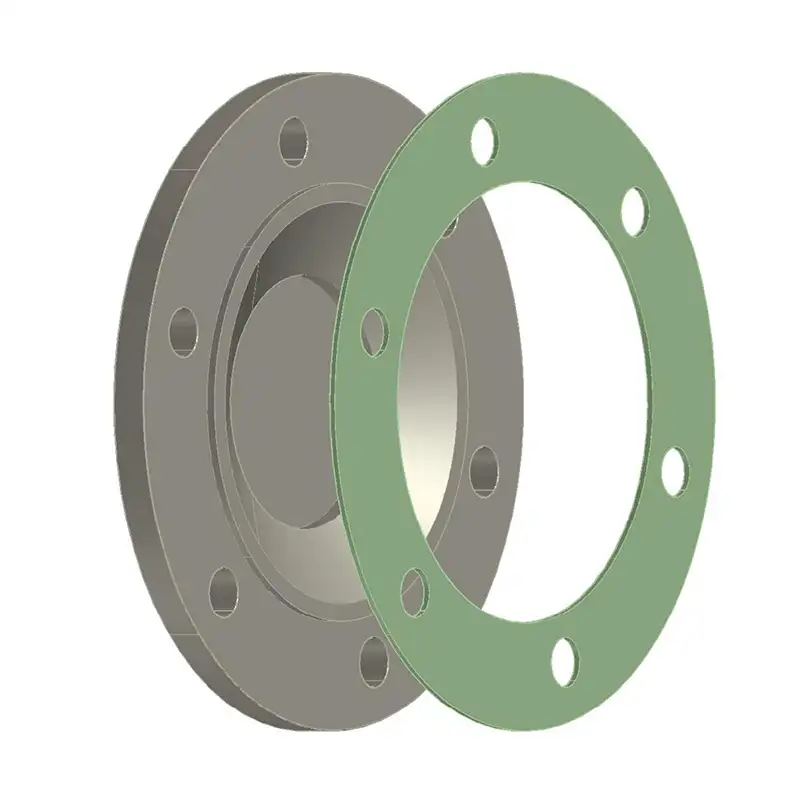

Rotating Plows

Parts are inspected and repaired or refurbished in accordance with service criteria, once a fixed price has been submitted and agreed .

Pendulum Mills

Fernite Engineering can replace all parts of the pendulum assembly. From a simple ring to a full new pendulum, we’re the one-stop-shop for all your refurb, repairs & replacement parts.

When your pendulum arrives at Fernite Engineering we complete a full inspection, advising on any replacement parts required, agreeing the scope of work required prior to any work being undertaken.

Our replacement rollers are manufactured using an improved material from the original OEM cast product, having a hardness level of 60hrc compared to the OEM’s 40hrc rollers. Additionally, our rollers can be re-worked up to 4 times, using our specialised welding process that returns the roller to an as-new condition. OEM supplied cast products cannot be re-worked.

Any other parts needing replacement will be detailed on our quotation and will be manufactured while your other parts are refurbished or repaired.

We do all the above at a significantly reduced lead time when compared to OEM-provided replacements. We work up to 4x faster, reducing a 6-month lead time to supply replacement parts to only 6-8 weeks to inspect, replace and re-assemble the whole pendulum unit.

The speed of this service allows customers to plan maintenance effectively and reduce process downtime to a minimum which improves productivity and maximises throughput.

Full inspection undertaken:

- Scope of work required is advised and agreed

- Fixed price quotation submitted

Replacement rollers are manufactured using improved material:

- Can last up to twice as long

- Can be re-worked up to 4 times (OEM cast products cannot be re-worked)

- Lead-time is typically 6-8 weeks, (OEM is up to 6 months)

Allows you to plan maintenance efficiently:

-

-

- Reduces maintenance

- Improves productivity

- Maximises throughput

-

Exceeded expectations

We needed a full new Pendulum Mill built to spec. Fernite Engineering delivered on time, on budget, and exceeded expectations on performance.

About us

Quality Service You Can Rely On, In the UK and Beyond

At Fernite Engineering, delivering a quality service isn’t just part of what we do, it’s at the heart of everything we stand for. Whether we’re repairing a single wear component or fully remanufacturing a Pendulum Mill, our focus is always on providing precision-engineered results, reliable lead times, and a level of customer care that sets us apart.

Trusted Nationwide, Respected Internationally

We proudly serve customers across the UK, supporting manufacturers, processors, and industrial operators with high-performance engineering solutions. But our reputation doesn’t stop at the border. With international clients returning time and again for our expert service and dependable delivery, Fernite Engineering has become a trusted name across the globe.

Engineering Excellence, Every Time

From our fully equipped facility, our experienced engineers handle everything in-house, from inspection and diagnostics to fabrication, refurbishment, and testing. This hands-on control ensures every job meets the highest standards of quality and consistency.

- In-depth knowledge of the specialist machinery required

- Fast turnaround times without compromising precision

- Proactive communication from start to finish

- Dedicated account management for smooth project delivery